DFT: Check Valves:

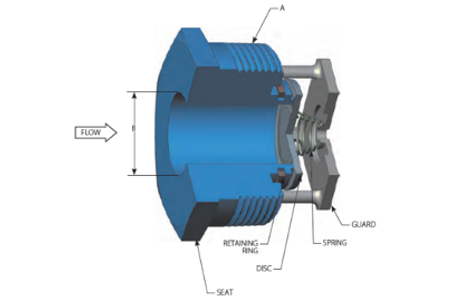

Vacuum Breaker Threaded Check Valve

|

|

| Documentation: Product Specifications (189KB PDF) |  |

Check Valve Operation:

Check valves are flow sensitive and rely on the line fluid to open and close. The internal disc allows flow to pass forward, which opens the valve. The disc begins closing the valve as forward flow decreases or is reversed, depending on the design. The function or purpose of a check valve is to prevent reverse flow.

Internal sealing of the check valve disc and seat relies on “reverse” line pressure as opposed to the mechanical force used for on/off valves. Because of this, allowable seat leakage rates are greater for check valves than with on/off valves.

| Vacuum Breaker Valve

|

Options:

|

|

In piping systems, DFT® Vacuum Breakers are used to break siphons, prevent pipe collapse during transient pressure drops, and to provide addition of air on the downstream side of check valves to dampen water hammer.

| Vacuum Breaker | Cracking Pressure | ||||

|---|---|---|---|---|---|

| A Nominal Size (MNPT) | B Unthreaded Inlet Bore | Weight | Cv | PSI | Inches of Water |

| 1 | 0.56 | 0.38 | 5.8 | 0.60 | 16.7 |

| 1-1/2 | 0.88 | 0.88 | 13.2 | 0.45 | 12.5 |

| 2 | 1.09 | 1.25 | 23.1 | 0.38 | 10.5 |

| 2-1/2 | 1.50 | 2.25 | 36 | 0.20 | 5.5 |

| 3 | 1.72 | 3.75 | 57.4 | 0.14 | 3.9 |

| 4 | 2.22 | 7.00 | 90 | 0.15 | 4.3 |

| Cold, Non-Shock Pressure Rating | ||||||

|---|---|---|---|---|---|---|

| 1" | 1-1/2" | 2" | 2-1/2" | 3" | 4" | |

| Vacuum Breaker BSSV | 2500 | 2000 | 1500 | 850 | 700 | 450 |

| Vacuum Breaker BSSV6 | 6000 | 5500 | 3000 | 1100 | 900 | 450 |

|

Sat. Steam Pressure |

Temperature (°F) |

Adjusted Rating as Percent of Cold Rating |

|---|---|---|

| -3 | 200 | 86% |

| 15 | 250 | 82% |

| 52 | 300 | 78% |

| 232 | 400 | 71% |

| 407 | 450 | 69% |

| 665 | 500 | 66% |

| 1526 | 600 | 62% |

| 3075 | 700 | 60% |

|

All stainless steel construction is suitable for cryogenic service. For pressure rating at elevated temperatures for standard metal-seated valves, reduce rating per chart above. Maximum valve temperature rating is limited by soft seal and spring materials in chart above. |

||

|

Materials of Construction |

Vacuum Breaker BSSV |

High Pressure Vacuum Breaker BSSV6 |

|---|---|---|

| Seat | 303 SS | 316 SS |

| Disc | 316 SS | 316 SS |

| Guard | CF8M | CF8M |

| Spring | 316 SS | 316 SS |

| Retaining Ring | 316 SS | 316 SS |

| A C U U M B R E A K E R V A L V E | |||||||

|---|---|---|---|---|---|---|---|

| | |||||||

| Part # | Size | Nominal Size (MNPT) A | Unthreaded Inlet Bore B | CV | Valve Cracking Pressure | Cold Working Pressure | |

| 8033 | DN 25 1 in | 1.00 in | 0.56 in 14 mm | 5.8 | 0.60 psi 0.041 bar 16.7 in.water 424 mm.water 31.1 mmHg | 0 - 2500 psig 0 - 172 barg | |

| 8103 | DN 25 1 in | 1.00 in | 0.56 in 14 mm | 5.8 | 0.24 psi 0.017 bar 16.7 in.water 424 mm.water 31.1 mmHg | 0 - 2500 psig 0 - 172 barg | |

| 8034 | DN 40 1.5 in | 1.50 in | 0.88 in 22 mm | 13.2 | 0.44 psi 0.030 bar 12.1 in.water 307 mm.water 22.6 mmHg | 0 - 2000 psig 0 - 138 barg | |

| 8035 | DN 50 2 in | 2.00 in | 1.09 in 28 mm | 23.1 | 0.36 psi 0.025 bar 10.1 in.water 257 mm.water 18.8 mmHg | 0 - 1500 psig 0 - 103 barg | |

| 8036 | DN 65 2.5 in | 2.50 in | 1.50 in 38 mm | 36 | 0.16 psi 0.011 bar 4.5 in.water 114 mm.water 8.4 mmHg | 0 - 850 psig 0 - 58.6 barg | |

| 8037 | DN 80 3 in | 3.00 in | 1.72 in 44 mm | 57.4 | 0.15 psi 0.010 bar 4.2 in.water 107 mm.water 7.8 mmHg | 0 - 700 psig 0 - 48.3 barg | |

| 8038 | DN 100 4 in | 4.00 in | 2.22 in 56 mm | 90 | 0.10 psi 0.007 bar 2.6 in.water 66 mm.water 4.8 mmHg | 0 - 450 psig 0 - 31.0 barg | |

| 8094 | DN 25 1 in | 1.00 | 0.56 in 14 mm | 5.8 | 0.60 psi 0.041 bar 16.7 in.water 424 mm.water 31.1 mmHg | 0 - 6000 psig 0 - 414 barg | |

| 8095 | DN 40 1.5 in | 1.50 in | 0.88 in 22 mm | 13.2 | 0.44 psi 0.030 bar 12.1 in.water 307 mm.water 22.6 mmHg | 0 - 5500 psig 0 - 379 barg | |

| 8096 | DN 50 2 in | 2.00 in | 1.09 in 28 mm | 23.1 | 0.36 psi 0.025 bar 10.1 in.water 257 mm.water 18.8 mmHg | 0 - 3000 psig 0 - 207 barg | |

| 8097 | DN 65 2.5 in | 2.50 in | 1.50 in 38 mm | 36 | 0.16 psi 0.011 bar 4.5 in.water 114 mm.water 18.4 mmHg | 0 - 1100 psig 0 - 75.8 barg | |

| 8098 | DN 80 3 in | 3.00 in | 1.72 in 44 mm | 57.4 | 0.15 psi 0.010 bar 4.2 in.water 107 mm.water 7.8 mmHg | 0 - 900 psig 0 - 62.1 barg | |

| 8099 | DN 100 4 in | 4.00 in | 2.22 in 56 mm | 90 | 0.10 psi 0.007 bar 2.6 in.water 66 mm.water 4.8 mmHg | 0 - 450 psig 0 - 31.0 barg | |

Designed to prevent Water Hammer

By the time the flow stops, the disc is closed against the seat preventing flow reversal. This prevents the valve from slamming closed which can cause “Water Hammer” and the resultant noise and damage to piping systems.

Liquids, gas or steam

All DFT non-slam check valves provide positive shutoff for applications involving liquids, gas or steam and can be used in most industries including oil and gas, petrochemical, pulp and paper, textiles and more.Meet or exceed MSS SP-61 leakage requirements

Available with soft seats for bubble-tight shutoff.