Ultrasonic Flow Meters: DXN

The DXN: Portable Hybrid

Transit Time/Doppler Ultrasonic Flow Meter

in response to changes in the liquid media in the pipe.

The NEW DXN is simply the best option for your next portable application, with true hybrid transit time and Doppler operation, an expandable 1GB data logger that takes readings over 50 times a second, and the ability to store site-specific parameters using plain English site names. Take control of your toughest applications, add the DXN Portable to your flow measurement toolkit today.

The DXN gives youunprecedented levels of portable ultrasonic flow measurement witha 7” color touchscreen interface that adapts to suit the needs ofyour application and a compact design that puts everything youneed in one convenient over-the-shoulder bag, all while providingthe level of accuracy you’ve come to expect from the leader inultrasonics, Dynasonics.

Rental Meters:

Daily / Weekly / Monthly Rates

DXN Hybrid

- Transit Time

- Doppler

- Onboard Battery

- Onboard Data Logger

- Export to USB Drive

- Energy Meters Available

- Windows Touchscreen

The DXN Portable Ultrasonic Flow and Energy Meter is a true hybrid instrument, capable of measuring liquid flow with multiple technologies, including: Doppler, transit time and liquid thermal (heat energy) flow. Easy to install by clamping onto the outside of the pipe, the DXN measures flow using non-invasive ultrasonic sensors. Compatible with a pipe wall thickness gauge, inside pipe diameter can be verified to ensure accurate ultrasonic measurements when piping details are unknown or unavailable.

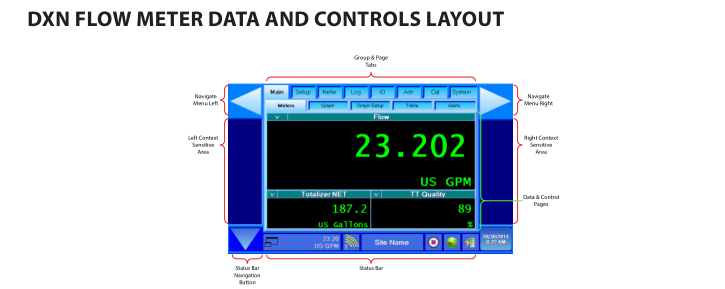

The DXN has a number of advanced features including a touchscreen interface, full-color graphing, wizard-based start-up configuration, USB connectivity, and Modbus TCP/IP connectivity. These features make it easy for technicians to obtain accurate readings while capturing flow surges and high-speed batch operations. The DXN captures and displays multiple user-defined and application parameters at once and can record the data with an easy-to-use data logging function. The ability to monitor and record several parameters at once allows technicians to verify and troubleshoot permanent flow installations with ease.

Transit time flow meters measure the time difference between the travel time of an ultrasound wave going with the fluid flow and then against the fluid flow. This time difference is used to calculate the velocity of the fluid traveling in a closed-pipe system. The transducers used in transit time measurements operate alternately as transmitters and receivers. Transit time measurements are bi-directional and are most effective for fluids that have low concentrations of suspended solids.

Doppler flow meters operate by transmitting an ultrasonic wave from a transducer through the pipe wall and into the moving liquid. The sound wave is “reflected” by suspended particles or bubbles moving with the liquid and ultimately gathered by the receiving transducer. A frequency shift (Doppler effect) will occur that is directly proportional to the speed of the moving particles or bubbles. This shift in frequency is interpreted by the digital signal processor (DSP) and converted to a fluid velocity measurement.

Using its built-in hybrid technology, the DXN will automatically choose which type of flow measurement to read based on signal quality during operation. Regardless of the method used to determine velocity, multiplying the pipe’s cross-sectional area by the fluid velocity produces a volumetric flow rate. The measurement also presumes that the pipe is completely full during the measurement cycle.

When used in conjunction with flow measurement, temperature measurements can yield energy usage readings in the form of heat flow. To find the net heat loss or gain, energy usage is calculated by multiplying the flow rate of the heat transfer fluid by the change of heat content in the fluid after it has done some kind of work.

An ultrasonic meter equipped with heat flow capabilities measures the rate and quantity of heat delivered or removed from devices such as heat exchangers. The instrument measures the volumetric flow rate of the heat exchanger liquid, the temperature at the inlet pipe and the temperature at the outlet pipe.

| Process Monitoring Inputs/Outputs: | |

|---|---|

| Connector | 15-pin high-density DSUB |

| Breakout Box | 0.2 in. quick disconnect screw terminal; 15-pin to adapter box; 6 ft (1.8 m) of cable (DSUB to DSUB connectors) |

| Analog Inputs/Outputs | Energy/Temperature (2) tab type PT1000 RTDs. Can handle various temperature ranges from –58 - 570º F (–50 - 300º C), based on RTD type Current output 4 - 20 mA active/passive 1% accuracy |

| Digital Output | Open collector, external pull-up; Rate or total pulse user selectable Rate pulse: 0 - 1000 Hz, Total pulse: 33 ms duration |

| Digital Input | Totalizer reset, external pull-up, software enabled |

| Auxiliary Inputs | Voltage input. 0 - 5V or 0 - 10V, 1% accuracy, Software scaling and control, 80 k Ohms input impedance, Data log capable |

| Voltage Output | 0 - 5V or 0 - 10V output voltage, 1% accuracy, Software scaling and control, 100 Ohms output impedance |

| System: | |

| Measurement Type | Flow: Ultrasonic transit time and Doppler (reflection of acoustic signals); hybrid operation; liquid thermal energy Pipe wall thickness: Ultrasonic transit time of acoustic signals |

| Liquid Types | Liquid dominant fluids, acoustically conductive |

| Velocity Range | Transit Time: Bi-directional to 40 FPS (12 MPS) Doppler: Uni-directional to 40 FPS (12 MPS) |

| Flow Rate Accuracy | Transit Time: ±1% of reading or ±0.01 FPS (0.003 MPS), whichever is greater. Doppler: 2% of full scale |

| Flow Sensitivity | 0.001 FPS (0.0003 MPS) |

| Repeatability | ±0.1% of reading |

| Temperature Accuracy | Absolute: 0.5° F (1° C) Difference: 0.2° F (0.5° C) Resolution: 0.02° F (0.01° C) |

| Logging | Greater than 300 sites stored in 1 GB; download to USB flash drive |

| Update Time | 0.1 - 10 seconds update/filter rate. Transit time, up to 50 Hz high speed mode |

| Battery | Internal 11.1V lithium ion battery, 75 W-hr. 6 - 9 hr of continuous operation with battery. Indefinitely on external power. Complete charge at 32…104° F (0…40° C), 4 hours when powered off. |

| Power Requirements | Transmitter: 10 - 30V DC via 3-pin connector, 40 W, minimum; 3.6 A re-settable fuse Supplies: Desktop adapter: 100 - 240V AC 50/60 Hz 50 W 10 - 18 V; Cigarette lighter adapter: 5 A fused |

| Power Cords | North American plug (2 flat & 1 round prong; NEMA 5/15P); Chinese plug (3 flat prongs; GB2099); Euro plug (2 round prongs; CEE7/7); U.K./Singapore plug (3 rectangular prongs; BS1363A) Japanese plug (2 flat & 1 round, JIS8303, w/ 3-2 prong adapter) Australian plug (3 flat prongs, AS3112) |

| Display | 800 × 480 WVGA color outdoor readable display; gloved-operation resistive touch screen 6 in. × 3.6 in. (152.4 mm × 41.44 mm) |

| Ambient Conditions | Battery powered: –4 - 110° F (–20 - 45° C) Externally powered: –20 - 140° F (–30 - 60° C) |

| Storage Temperature | Do not exceed 175° F (80° C) |

| Enclosure | Water/dust resistant |

| User Menu | Multi-language: English, Spanish, German, French, Portuguese, Japanese, Russian, Italian, Dutch, Norwegian, and Swedish |

| Compliance | Safety: UL61010-1, CSA C22.2 No. 61010-1, EN61010-1 Directives: 2006/95/EC low Voltage, 2004/108/EC EMC |

| Transducers: | |

| Pipe Sizes | 1/2 in. and larger; US standard pipe tables are built into user Interface |

| Housing Material | DTTSU: CPVC, Ultem®, and anodized aluminum track system; nickel-plated brass connector with Teflon® insulation DTTR: PBT glass filled, Ultem, Nylon cord grip, PVC cable jacket DTTL/DT94: CPVC, Ultem®; nickel-plated brass connector with Teflon® insulation DTTH: PTFE, Vespel, Nickel-plated brass cord grip PFA cable jacket |

| Pipe Surface Temperature | DTTSU/DTTL: –40 - 194° F (–40 - 90° C) DTTR: –40 - 250° F (–40 - 121° C) DT94: –40 - 194° F (–40 - 90° C) DTTH: –40 - 350° F (–40 - 176° C) |

| Transducer Frequency | DTTSU: 2 MHz DTTR/DTTH: 1 MHz DTTL: 500 kHz DT94: 625 kHz |

| Cable Length | Transit time: 20 ft (6 m) paired coaxial cable, BNC to BNC, Doppler: 20 ft (6 m) paired coaxial cable, BNC to 4-pin |

| Pipe Thickness | Dual mode transducer with 6 ft (1.8 m) of cable (BNC ends) |

| RTDs | 2 x platinum 385, 1000 Ohm, 3-wire PVC jacketed cable standard with quick connector |

| Basic |

|

| Transit Time Standard Temperature |

|

| Hybrid |

|

| Energy |

|

| Full |

|

| Power Cords and Cables | |

|---|---|

| Part Number | Description |

| D005-2109-013 | North American Plug (2 flat & 1 round prong; NEMA 5/15P) |

| D005-2109-015 | UK Plug (3 rectangular prongs; BS1363A) |

| D005-2109-016 | European Plug (2 round prongs; CEE7/7) |

| D005-2109-017 | Japan Plug (2 flat & 1 round, JIS8303, w/ 3-2 prong adapter) |

| D005-2109-014 | China Plug (3 flat prongs; GB2099) |

| D005-2109-018 | Australian Power Plug (3 Flat Prongs; AS3112) |

| D005-2129-020 | Transit Time Cables, 20 ft (6 m) |

| D005-2129-050 | Transit Time Cables, 50 ft (15 m) |

| D005-2129-100 | Transit Time Cables, 100 ft (30 m) |

| D005-2130-020 | Doppler Cables, 20 ft (6 m) |

| D005-2130-050 | Doppler Cables, 50 ft (15 m) |

| D005-2130-100 | Doppler Cables, 100 ft (30 m) |

| Transducers (Heads with Case) | |

| D010-2200-002-C | DTTSU Universal Small Pipe (Pipe O.D. 0.5 in. to 2.4 in - 12mm to 60.3mm) |

| D071-0107-302-C | DTTR Standard Pipe (Pipe O.D. 2.0 in. to 98 in - 50mm to 2500mm) |

| D071-0110-200-C | DTTL Large Pipe (Pipe O.D. 16 in. to 120 in - 400mm to 3050mm) |

| D071-0112-001-C | DT94 Doppler Transducer (Pipe O.D. 1 in. to 60 in - 25mm to 1524mm) |

| DTTH-020-D000-N-C | DTTH High Temperature, Standard Pipe Kit (Pipe O.D. 2 in. to 98 in - 50mm to 2500mm) |

| Spare Parts | |

| D002-2007-004 | 0 - 392 °F (0 - 200 °C) RTD Silicone stretch tape |

| D002-2007-001 | 36 in. (914 mm) SS Hose clamp / transducer strap |

| D002-2007-005 | 72 in. (1829 mm) SS Hose clamp / transducer strap |

| D002-2011-014 | AcquaSonic 100 |

| D002-2011-001 | Acoustic couplant, grease (Dow 111), 150 °F (65 °C) 5.3 oz (150.2 gram) tube |

| D002-2011-011 | Acoustic couplant, paste high temperature, 5 oz (142 gram) tube, 392 °F (200 °C) |

| D010-2102-310 | DTTR rail |

| D040-0115-003-T | Wall thickness gauge, 6 ft (1.83 m) |

| D010-3000-128 | Industrial RTD Kit 1 , 1000 Ohm, 392 °F (200 °C); 20 ft (6 m) cable* |

| D010-3000-130 | Industrial RTD Kit 1 , 1000 Ohm, 392 °F (200 °C); 50 ft (15 m) cable* |

| D010-3000-132 | Industrial RTD Kit 1 , 1000 Ohm, 392 °F (200 °C); 100 ft (30 m) cable* |

| *RTD Kits include 2 RTDs, heat sink compound and installation tape. | |